In modern residential and commercial design, countertops serve more than just functional purposes. They anchor the kitchen, define the workspace, and often become the centerpiece of the room. Materials like stone and quartz dominate the market, but for projects requiring a bold yet refined statement, glass countertops — especially those engineered by fusion — offer unmatched clarity, strength, and customization.

Read more: Precision and Aesthetic Brilliance in a Single SurfaceThinkGlass has redefined what glass can achieve in architectural applications. By mastering the fusion technique, they have made it possible to craft countertops up to 12 inches thick, luminous in appearance, impervious to wear, and highly customizable. These are not traditional glass surfaces — they are structural, sculptural, and engineered to outperform.

Solid fused-glass mass: not your typical panel

Unlike laminated or tempered glass, which are layered or surface-treated, fused glass is a monolithic structure. It is created by stacking multiple layers of high-quality glass and heating them in a kiln at controlled temperatures until they meld into a single unified piece.

This process eliminates any seams, adhesives, or points of weakness. The result is a solid slab of fused glass with uniform strength throughout its thickness. ThinkGlass countertops can reach 3 inches standard thickness, and even go up to 12 inches for dramatic visual effect. These massive volumes of glass still retain their clarity — a testament to the purity of the raw materials and the precision of the fusion process.

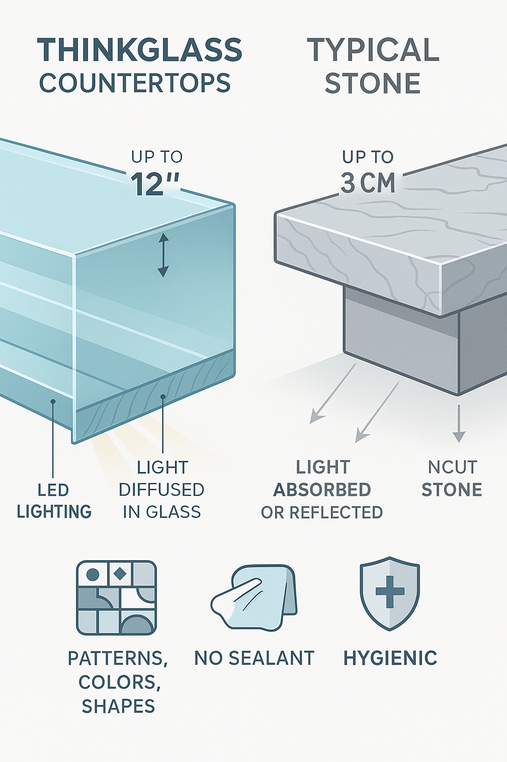

| Specification | ThinkGlass Countertop | Typical Stone Countertop |

| Maximum Thickness | Up to 12 inches | Usually 3 cm (~1.2 inches) |

| Structural Span | Up to 36 inches unsupported | 12–20 inches (with support needed) |

| Visual Depth | Multidimensional, luminous | Flat or veined |

| Weight Support | Hundreds of pounds, structure-rated | High, but varies by stone |

| Customization | Full shape, texture, edge, color | Limited by slab availability |

| Maintenance Needs | No sealant, easy wipe-down | Requires regular sealing |

This thickness contributes to enhanced structural performance, better acoustics, and deep optical effects that give each slab an unmistakable sculptural presence.

Texture beneath the surface: optical function and daily durability

ThinkGlass countertops are textured on the underside, an engineering decision that provides both visual and practical advantages. Unlike surface textures that wear out or accumulate grime, the underside texturing remains protected, enhancing the play of light through the slab without compromising hygiene or cleanability.

This sub-surface texturing:

- Conceals scratches and fingerprints from above

- Softens reflected light and eliminates glare

- Gives the countertop a distinctive, tactile look without maintenance burdens

The textures themselves range from subtle organic waves to bold abstract patterns. Each is crafted using proprietary molds and can be customized per project — a capability unmatched by traditional countertop materials.

Clients may choose between three edge finishes — brushed, polished, or textured — each offering different levels of reflectivity and tactile perception, depending on the surrounding materials and light conditions.

Seamless lighting integration: from surface to sculpture

One of the most striking features of a ThinkGlass countertop is its ability to integrate lighting without visible fixtures or complex installations. The translucency of the fused glass, combined with its uniform density, makes it an ideal medium for edge-lit or backlit LED illumination.

ThinkGlass offers plug-and-play LED systems designed specifically for their glass countertops. These systems require no electrician, no special embedding, and no technical adjustments — making the integration as simple as placing the countertop on its base.

Lighting in countertops is no longer a gimmick; it becomes an architectural tool. It can:

- Define work zones

- Add ambiance in hospitality settings

- Replace task lighting in minimalist kitchens

- Serve as night illumination in bathrooms or hotel suites

The result is a functional light source that also becomes a design signature.

Hygiene and maintenance: superior to natural stone

Hygiene is a crucial factor in any surface that supports food prep or frequent human contact. Unlike porous materials such as marble, granite, or even some engineered stones, ThinkGlass countertops are completely non-porous. This means:

| Feature | ThinkGlass Countertop | Natural Stone |

| Porosity | Non-porous surface | Porous – absorbs moisture and oils |

| Cleaning | Microfiber cloth, non-abrasive cleaner | Special stone cleaner recommended |

| Sealing Required | No sealant ever needed | Regular resealing required |

| Stain Resistance | Excellent — does not absorb pigments | Vulnerable to stains (e.g., wine, oil) |

| Fingerprint Visibility | Reduced by underside texturing | High, especially on polished granite |

This resistance to contamination makes ThinkGlass a preferred choice in chef kitchens, luxury bathrooms, tasting rooms, and healthcare environments where aesthetics and cleanliness must go hand in hand.

Structural performance: ready for the demands of daily life

ThinkGlass countertops are not fragile or decorative elements — they are load-bearing, impact-resistant surfaces that comply with the most rigorous building codes in North America, including the Quebec construction code.

Key performance characteristics include:

- Weight tolerance: Capable of supporting hundreds of pounds without reinforcement

- Thermal resistance: Withstands high-heat cookware, UV, and freezing conditions

- Impact behavior: More durable than traditional glass due to its fused mass structure

The same fusion process used in ThinkGlass countertops is used in their stair treads, which are tested to support up to 1,800 lbs per step — reinforcing the confidence in their countertop applications.

Substrate design: maximizing light and concealing structure

Behind the visual simplicity of a ThinkGlass countertop lies a thoughtful installation system. To preserve the purity of the glass, substrates must be carefully selected. The recommended bases include aluminum laminates or metallic laminates, which:

- Reflect light back through the glass, enhancing brightness

- Mask cabinet interiors and support brackets

- Prevent visual shadows or dimming when backlighting is used

ThinkGlass provides detailed documentation and installation recommendations, ensuring that lighting effects and structural performance are preserved from blueprint to final delivery.

Applications: residential elegance to commercial impact

ThinkGlass countertops have been successfully integrated into:

- Custom kitchen islands in high-end homes

- Executive bathroom vanities

- Boutique hotel bars and reception desks

- Open-concept chef kitchens and tasting rooms

- Museum counters and public installations

Each countertop can be shaped, tinted, engraved, or textured to meet branding needs or to enhance architectural harmony with other materials like wood, metal, and stone.

A signature material that elevates any space

ThinkGlass countertops are not merely functional surfaces — they are an investment in artistry, durability, and environmental quality. With low-maintenance requirements, superior optical clarity, and engineering-grade resistance, they serve as a cornerstone for projects that seek to impress without compromise.

Whether specified for a luxury residence or a landmark public space, a ThinkGlass countertop embodies the intersection of craft, material science, and modern architecture.

For more information ; Chloé Lewis